If a tree falls in a forest and no one is around to hear it, does it make a sound? If you win a prestigious national award and didn’t even know you were entered, does it feel less sweet? One philosophical; one very real to Sean Hendry, safety director at APG in Clearwater, FL, and winner of the 2022 IEC Safety Professional of the Year Award.

“Winning the award was a total surprise to me, as I didn’t even know my team had submitted my name,” says Sean. “I learned of the win via text from my student Tim Turner who was at SPARK 2022 for the Apprentice of the Year competition and he was at the reception when my name was called. It was truly a humbling experience especially when I learned of the recommendations some of our customers took the time to write and submit to IEC.”

Hopping on to the Safety Road

Hopping on to the Safety Road

Sean is 100 percent totally convinced that electrical contracting companies must have that commitment to safety from senior management if it is going to succeed. And, Sean says, that’s the case at APG. He’s been safety director for almost 10 years now and the first APG employee to secure that full-time position. Previously, it was handled by the company COO in addition to his other duties. As the company grew and projects increased, APG wanted an employee dedicated to safety.

“Shortly after joining APG in 2011, I was put on a big job — St. Joseph’s Hospital in Riverview, FL, managing all the temporary power systems,” Sean says. “It was a major building — more than 500,000 square feet. The general contractor had advised APG that it was a requirement that each subcontractor have its own safety representative. APG selected me and made sure I was trained — I did an OSHA 30 and other online training in addition to handling my field work.”

Sean’s safety skillset developed in the course of the year-and-a-half he was on the St. Joseph’s project, and he was energized by the opportunity to see that all APG workers involved in the project were safe doing their work. He says APG as a company was growing exponentially at the time and Sean got word that management felt it was time to have a full-time safety director for the company.

“While I’d only been with the company a couple of years and wasn’t sure I really had a chance at the spot, I sent an email to Executive Vice President Chris Johnson asking him to throw my name into the hat,” Sean remembers.

He had the field experience, he had the work ethic, and he had proven he had the safety knowledge through his role at St. Joseph’s. He was given the job.

Fast forward about 10 years. APG has continued to grow, and Sean continues to help ‘his guys’ keep safety top of mind.

“We don’t want to be the safety police,” he says. “We want to be a resource. We want people to be able to come to us and feel comfortable asking questions, requesting additional training, reporting challenges, and feeling supported.”

The APG Safety Program

Sean acknowledges that a safety culture was in place and amazing when he got there and he has been privileged to build upon it. He says APG provides a lot for its employees in terms of training, tools, and equipment. For example, workers are given an allowance to cover safety boots, prescription safety eyewear, shirts and sleeves for weather extremes, gloves, hard hats, shades for their hard hats, neck gators, and more.

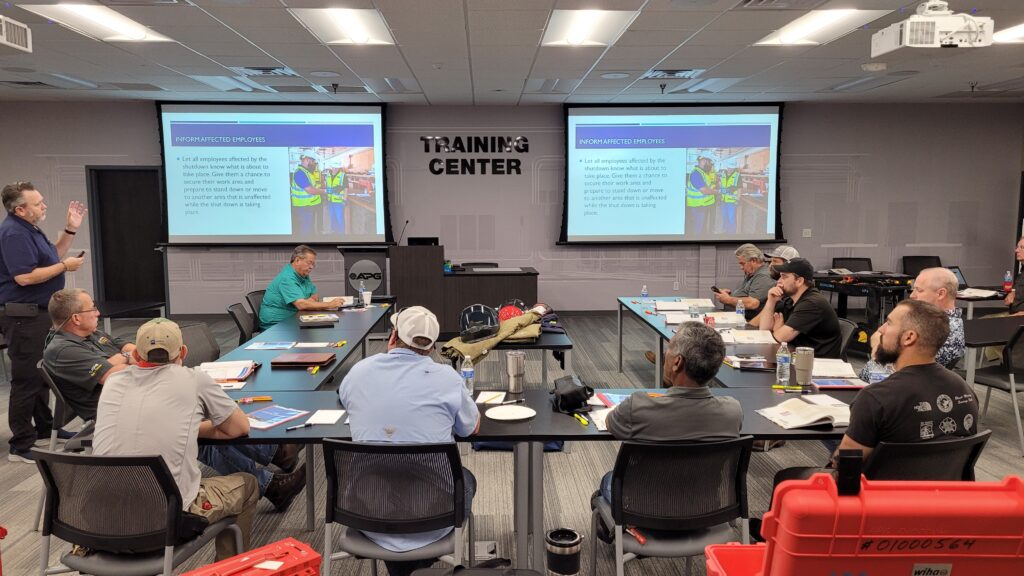

Classroom training includes OSHA 10, OSHA 30, CPR, fire alarm, NFPA, arc flash hazard, and codes and standards. Sean himself is an authorized OSHA instructor, so he teaches OSHA 30 and OSHA 10 classes for all employees.

“You have to keep up with the changes and the technology,” Sean explains. “You also need to recognize that the younger generation learns differently, so I’m always looking to adjust how things are taught, how we get messages across, how we help everyone to learn and feel comfortable.”

He says he is constantly testing new presentation methods. Recently, he tried out a new room setup for classes —a U shape to encourage discussion and sharing of information — as well as making the class sizes smaller.

“There is always a lot of experience in the room, and we wanted to encourage sharing that experience,” Sean says. “We received a great amount of positive feedback on that little adjustment. People appreciated the interaction.”

Another new training strategy was the introduction of virtual reality (VR) into their OSHA classes. In coordination with their insurance company, they simulate fall protection scenarios, confined space, and ladder safety.

“VR is that bridge of technology that younger workers are familiar with and it makes for a more engaging process,” Sean says. “It’s an interactive process because we broadcast what they are seeing in the headsets on screens in the room. It makes safety a little fun, because hearing me talk for 10 hours is a little boring.”

Onsite field training includes items specific to the jobsite and can include confined space, fall protection, lockout/tagout, large equipment operation, and rigging. Sean says when he or one of his compliance officers walks a job site for an audit, they always try to interact with the workers – ask how they are doing, request their input. Sean says one of the main benefits of field training is that it involves everyone — not just the foremen or supervisory staff. Each rank-and-file person doing the work benefits from education on site.

Another recent strategy came about in reaction to arc flash incident they had and, luckily, the employee made a full recovery. The company was very transparent about the incident and the factors surrounding it.

“We sat down and spent time analyzing what we should put together to help others learn from this incident that was the result of a violation of company policy by the injured employee,” Sean says. “We used this accident as a very real example of why safety matters; it was very personal for all employees and we wanted good to come out of it. What can we learn from it and how do we help someone else benefit from the incident?”

In another effort, Sean offers weekly toolbox topics to the APG team. He writes them himself, gears them appropriately to APG work, and covers any code changes. These are utilized in the pre-task morning meetings.

“Material is on the white board and open to employee input and team discussion,” Sean says. “We take every possible opportunity to push safety and keep it top of mind. All of this effort and attention puts a rubber stamp on the fact that the company wants to take care of its people. Our biggest challenge is the other guy, the other subcontractors who may not have the safety culture and policies that we believe in at APG. They might not maintain a safe working atmosphere for themselves, let alone the surrounding employees of other companies.”

Here again, APG stands behind its employees. They have been told from the top that if a team needs to walk off a site due to someone else’s lack of concern regarding safety, they can do it. Sean says usually the foreman can handle the situation, but Sean or his compliance officers step in if need be.

“It’s always better if it can be resolved by the foremen, as they are the ones who need to work with the other team on a daily basis and need to build those cooperative relationships,” Sean says. “I’m here to back them up, and my bosses are here to back me up.”

The Road to the Award

Being recognized by his peers and heralded at the national level as having made a difference pleases Sean tremendously. While safety ultimately lies with the individual, Sean knows he is responsible to facilitate understanding and provide each worker with the training, tools, and equipment to do their jobs well and safely. He is grateful for his safety team members —Senior Safety Compliance Officer Dale Rive and Compliance Officer Dale Kimball.

“Winning this award is humbling, but I am proud,” he says. “I’m fortunate to have access to the best curriculum in the business through IEC. I am then free to add a little bit more to take it to another level for our work circumstances. But knowing that locally and nationally, there are dedicated people making sure material is up-to-date, interesting, energizing, and creative in terms of labs for example, makes my job that much easier.”

He knows that putting safety first across the board means that being an electrician will continue to be a great career path for many in years to come.

Set Yourself Up for the Winners Circle

Do you want to be like Sean? Or like one of the other numerous winners of IEC National Awards?

Applications are being accepted for the 2023 IEC National Awards through July 17.

Nominations are encouraged from members and chapters in the following areas:

- Excellence in Electrical Construction (Residential; Commercial; Industrial; Low Voltage/Limited Energy Green; Service)

- Individual (Member of the Year; Apprenticeship Alumni; Rising Stars)

- Chapter (Apprenticeship Chapter of the Year; Legislative Chapter of the Year; Chapter Executive Director of the Year; Chapter of the Year; Instructor of the Year)

- Achievement (Industry; Community Service; National Legacy; National Team)

- Safety (Safety Professional of the Year; Safety; Safety Program Awareness & Retention Kit (SPARK) Recognition)

Visit the website for specifics on each award’s qualifications, required items for nomination, and judging information to help you submit a successful application. Winners are announced — and celebrated — at SPARK 2023 in Dallas, TX, October 16-18.