Material issues have been on the rise, and fixture packages have been and continue to be one of the most difficult areas to manage, and one of the costliest items to mismanage. We all have experienced the impacts of the ongoing pandemic on manufacturing and supply chain predictability, however some choose to be victims and others choose to take charge and manage the outcome. If you chose not to be a victim, then you will need to assess and strengthen your material management process to combat the increased uncertainty that exists today.

Material management, and specifically the intricate details of fixture package management, is an area that has challenged contractors and their project managers for decades. For many contractors the attempted solution has been to pass this management responsibility upstream to the vendor that sells us the lighting package. Unfortunately, this has only been successful in special cases with very rigidly defined relationships operating with a clearly defined statement of work. For most businesses this success has not yet been achieved and the responsibility and burden for fixture packages remains with the contractor.

Managing the logistics of procurement, production, shipping, assembly, storing, kitting, and staging material is often far more complicated than managing skilled installers. There are many businesses, many personalities, and even more excuses to be dealt with when it comes to facilitating an effective supply chain result. Fortunately, there is a science behind this, a proven science for procurement and logistics management that can be used in the construction industry as effectively as it is used in any other. We will look at the steps required in this process and some simple tools to help make this daunting task manageable.

The key work for material logistics and fixture package management spans across several business processes including:

- Estimating

- Purchasing and AP

- Procurement, complete sourcing

- Project management

- Prefabrication, assembly, kitting, and carting

- Shipping, receiving, and onsite handling

- Billing, AR, and collections

This broad interaction within your business model is why simple and standardized tools are necessary to achieve a predictable result.

The tools that are needed include:

- Bill of Material from the estimate, broken down to include fixture types, fixture quantities, selected suppliers, and specific part numbers to be used. As an output from the estimation process the handoff to project management should also include the sourcing information used for pricing the package(s) and the reasons those vendors and items were selected. Additionally, if any of the provided fixtures represent an alternate or deviation from the original RFP then the handoff should also include details regarding the status of approval and any prepared submittals. All of this should be tracked in a simple worksheet that allows for easily making changes and tracking updates. Often changes can result in either increased time or increased cost, or both, and this can only be properly reflected in your contract value and schedule if you follow the terms for change order submission in your contract.

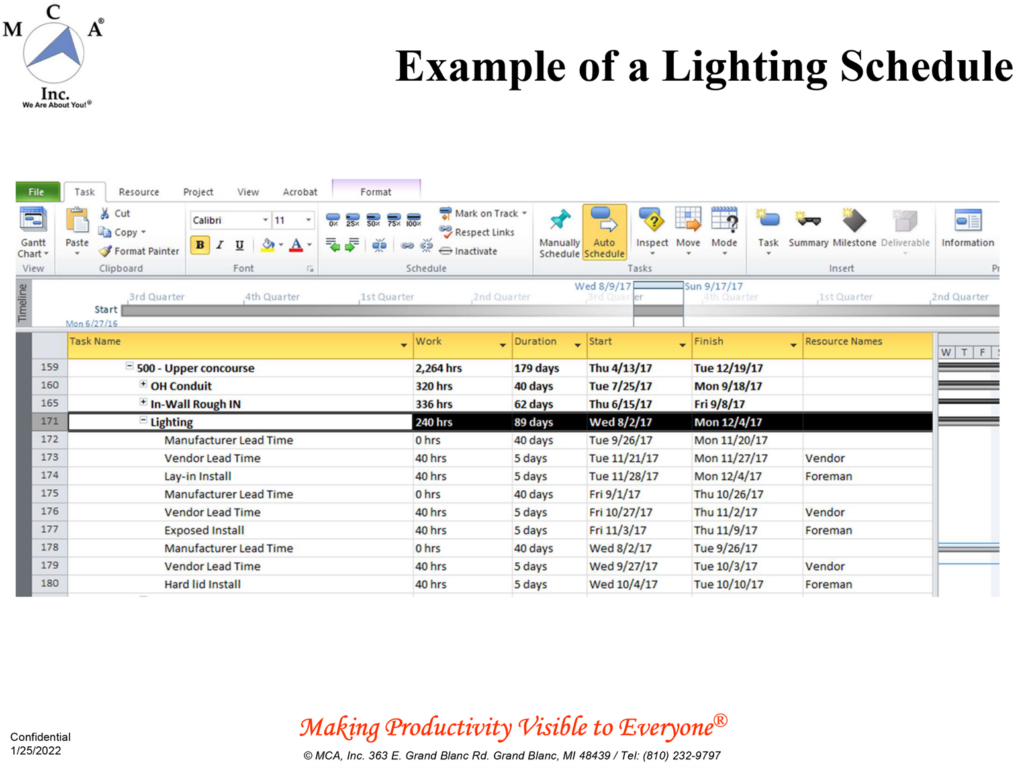

- Project Schedule should be complete and based on an interconnected and interactive project model (not just a manually generated Gantt chart in your favorite software application). In an effort to simplify and comply with contract requirements for scheduling, many contractors resort to programs like Excel, Visio, or other drawing tools that lack the actual analytic capability of a true scheduling tool. Even if a scheduling software is used, most of those we see produced by PMs are not based on an interconnected model to truly simplify the work of identifying the overall impact of changes. It’s never about knowing whether a schedule changed; the value is in knowing how the changes impact your work and your ability to meet the delivery expectations. Whether your customer requested a change, or whether the availability of even a single component is delaying a fixture type, you need to immediately know what impact a revised production or delivery date will have on your final installation goals. This complete interaction is only visible with a schedule that includes dynamic relationships between the tasks. Additionally, the Work Breakdown Structure (WBS) that is reflected in the schedule must include enough detailed work to be able to properly identify the necessity for lead times and buffers. For an example refer to Figure 1.

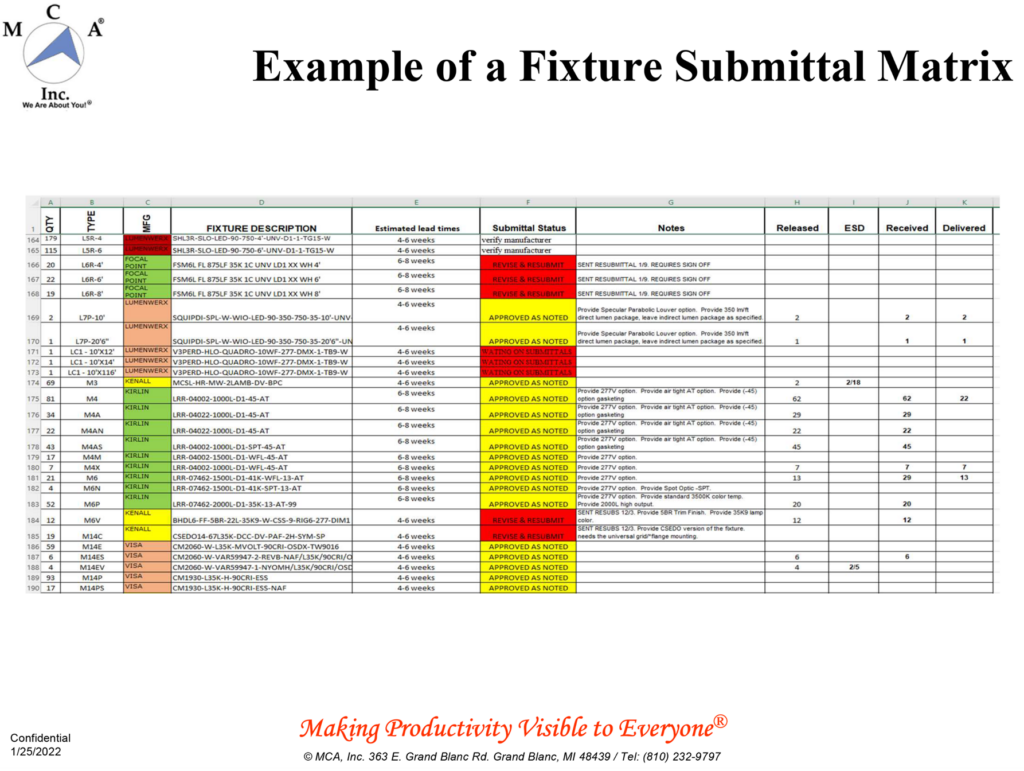

- Submittal and approval schedule and tracking Submittals are one of the most common sources of delays with fixture packages. You don’t want to issue a PO, and you certainly don’t want to release a fixture package with your vendor before it’s been approved by the customer. Every contract that includes specific material, such as fixtures, also includes requirements for submittal and approval of the fixture package. The project schedule needs to include the decision and response time lags that are in the contract. Only with the work of preparing submittals and the time involved with securing approvals built into the schedule can you predictably achieve the required release dates. Once established the submittal must occur on or before the planned submission dates and all submission and approval status and dates must be tracked. For an example refer to Figure 2.

- Purchase order tracking, with specific items, order dates, release dates, production dates and shipping / receiving dates. Your accounting system very likely has several reports for purchase orders open / closed status and amounts, along with dates issued and paid. What you need to track is what POs are going to be needed and when are they going to be needed (this ties back to the Bill of Materials and tracking changes to it as listed above). If you don’t know what you need to issue and when they need to be issued, then getting the fixture POs into the accounting system is often delayed. Delays getting the information into accounting restricts visibility into what is ordered and what is not and can create subsequent delays that can impact the timely availability and installation of the fixtures, not to mention accurate cost recognition.

- Inventory tracking to show where each item is located at any point in time, ideally with history to show the movement each item has taken to arrive in its current location. One of the costliest errors is to purchase long lead items, know we bought them and received them, but can’t find them when it’s time to install them. Not only is this costly and embarrassing, it’s also easily avoidable. Using a formal inventory management system like your vendors have in their warehouse is one option, but for those who don’t have that much to track, or that much budget for elaborate IT solutions, a simple worksheet that shows what has been received, when it was received, and where it has been stored can be an essential piece of the overall logistics management process. Chances are that you have ordered something online and tracked its movement across the country in real time, but do you know where every component of the $50,000 fixture package is in your building and on your job site?

Each of the steps included above and each of the tools described above and shown in the examples contain the information needed to plan for the fixture package and the work involved with procuring and installing the fixtures. All these forms and templates still require someone to use them and to make the decisions to detect and correct the issues as they occur and as they are detected. The key to fixture package management isn’t to pass the responsibility off to a vendor and hope for the best; the key is to gather and track the information needed for effective management, and increased predictability of the outcome, even in the face of significantly increased uncertainty in the supply chain. Once your process and your tools are proven to be effective, sharing the responsibility for individual tasks or overall management can be passed on to your vendor partners, effectively and without loss of visibility and control.

The reality is that some of your fixtures will not come to the job site when you expect them, some will not come out complete or as you need them. But, if you discover these shortfalls on the day you plan to install the fixtures, then it’s too late to make a new plan. You need to know when dates will be missed and when components will be delayed as soon as that information is knowable. And when you know, you need a project model that allows you to immediately see exactly what impacts that delay will create.

Alternate plans, shifting resources and priorities are the inevitable, and they are the adjustments that good project management and good material management will allow you to make effectively and efficiently while keeping all the stakeholders informed.

Figure 1: Example of a lighting schedule with vendor and manufacturer lead times built in.

Figure 2: Example of a fixture submittal matrix tracking approvals and releases